Printing gone viral?

We mentioned the importance of the printing press before in our series about Information Technology History, but the printing press has during the last decade been in a transitioning phase and “new” printing technologies are emerging all over the world and might provide the best environmental impact since a long time.

But lets take it back a bit an recognize the print technology’s evolution.

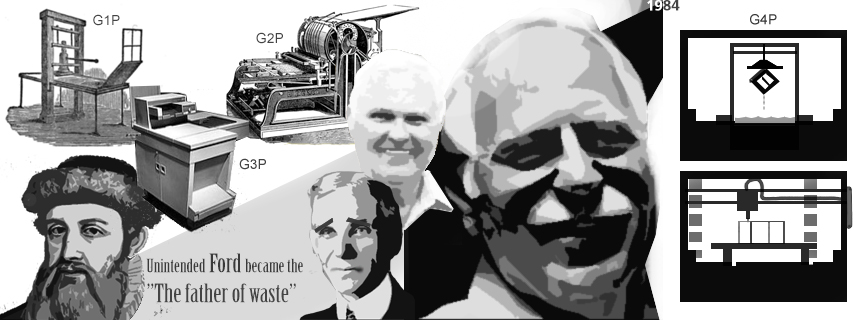

G1P : Generation 1 printing technology was the Gutenburg print press (1500 CE) that provided about 10x faster printing than the written word.

This first generation promise: Good for printing and securing knowledge and thoughts, that otherwise would be left unknown.

G2P : Generation 2 introduces upgrades with the steam engine (1800 CE), that provides a boost and increased printing speeds up to 50x times faster or more.

This generation promises: Good for printing the above gen-stuff, but also prints for the masses (Mass-media is born)

G3P : It’s not until around 1940/1950’s that the electrical printer starts to establish it self. In par with the computer evolution, printers also became more and more efficient and it is commonly said it was the Xerox model A producing about seven copies per minute and the Remington-Rand that could reproduce 600 lines per minute, that form the start of todays modern printing.

This generation promises: This generation are good for all above, but also facilitates more practical printing for both business and homes.

G4P :When the subject is about additive manufacturing, 3D printing, we have entered the realm of what we would call the 4th generation of printing technologies. Because we have now left storing knowledge behind, we have left printing for the masses behind and have started to focus on printing practicality as a means for production of anything… And it is the fourth generation this article will focus more on.

– This new tech might actually remove “The grand father of all waste”

The new generation still stems from the old printing press technology, but now *prints layers after layer making 3d objects, instead of printing 2D pictures, covers and text. By enabling printing on demand, this new tech might actually remove “The grand father of all waste” meaning the batch production system which currently is a bi-product of “the ford assembly line”. Meaning this 4th generation printing technology could transition more businesses to “Pull systems” that are based on actual demand rather then “Push Systems” that are based on forecasts, that creates production that needs to be stored, counted, transported, managed and discounted (more labor intensive, costly and produces more waste).

*Some of the technologies referred in the article actually do not print but burns/melts the layers with laser or electrons etc.

SWEIT thinks Additive Manufacturing also called 3d printing* (SLA, SLS, FDM, DLP, MJF, PJ,DMLS, EBM etc) technology might have similar affect on the world, as the steam engine printing had during the electromechanical era! Meaning this technology has the potential to be implemented on large scale and there for increase production rate in areas where it’s previously been out sourced or perhaps never been located before!

Only this factor alone, would provide great benefits for both business and the environment, and not least the customers. But with the technology potentially breaking up logistical networks and decreasing the need for storage, the world might soon see a different business model or world all together.

We are currently seeing the “first generation” of these replicator “like printers” and they are increasingly becoming faster. More and more new materials are being studied & produced every day in order to bring this technology to use and it will probably enable industries to re-allocate to the best environmentally friendly spaces available in terms of placing the production as close to the source you use to print with or where the majority of your customers are living.

However there are potential risks to. Ever heard about the “Gray goo theory“? It’s a hypothetical global catastrophic scenario based upon out-of-control self-replicating machines that consume all biomass on the planet. It’s actually kind of scary and looking at the progress made within this sector it almost feels like what was recently SCI-FI, is now made IRL.

But with the potential to reduce the amount of shipping made globally in terms of just producing a products where it is cheapest to produce labor wise and instead focus on the greater beneficial circles that could be made from less environmental impact, less labour, less storage and less shipping etc. This technology is poised to be developed further and have an BIG impact on the world. But as always, there are pros and cons with everything!

This generation promises:

Pros:

- 3D printing allows more complex designs than traditional manufacturing processes..

- Minimizes Waste/Print on demand

- Cost Effective.

- Ease of Access

- Flexible Design/Rapid Prototyping.

- Strong, durable and Lightweight Parts.

- Fast Design and Production.

Cons:

– Reduction in Manufacturing Jobs.

– Hazardous materials used in 3d printing technology (ex. razing & plastics being used)

– Potential for additional *hazardous materials to be invented/produced (“grey goo stuff”).

Even if there is a risk for more hazardous materials being invented, Additive Manufacturing technology will bring a revolution in what materials we all use in or day to day life’s!

This might as well (hopefully) create better approaches to how we produce stuff in general and in turn procures local economies and the local environment!

If applied with sense and foresight (that includes an eco-friendly mindset)… or what SWEIT aspire to promote: It would need a regenerative mindset to secure the future, not one singular aspect but in term of many factors that intertwine in network that should reflect and reference benefits to the environment, society and coming generations of living life and technology.

SWEIT hopes you want to be apart of a truly regenerative IT pursuit globally! So hopefully we can join forces and share insights, hope, expertise and know how, where it is badly needed!